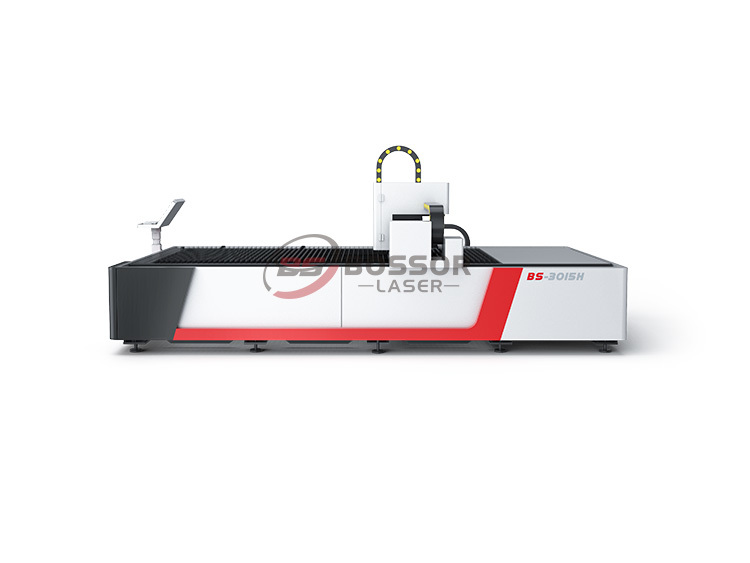

Operating table half cover full side

Classification:

Key words:

Operating table half cover full side

Product Description

Laser cutting principle:

Fiber laser cutting radiates high-intensity laser light to the metal surface, melts or vaporizes the metal through the interaction between the laser and the metal, and cuts the workpiece with the assistance of high-speed airflow. Metal melting is only one of the physical phenomena during the interaction between laser and metal. Sometimes, light energy is not mainly converted into metal melting, but manifests itself in other forms, such as vaporization, plasma formation, etc. However, for good melting to occur, metal melting needs to be the primary form of energy conversion. To this end, it is necessary to understand the various physical phenomena produced in the interaction between laser and metal and the relationship between these physical phenomena and laser parameters, so that by controlling the laser parameters, most of the laser energy can be converted into metal melting energy to achieve the purpose of cutting.

Description of the features of BS-G3015D-1000W fiber laser cutting machine;

The overall structure adopts fixed workpiece and movable gantry structure. It can realize two-axis linkage and three-axis control of X and Y-axis linkage to achieve plane cutting feed, and Z-axis floating tracking of the workpiece surface. The three CNC axes are guided by rolling guide rails, and the AC servo motor drives the ball screw pair for feed. The servo motor is selected from Japan's Yaskawa brand, and the guide rail, slider, and ball screw are selected from Taiwan's HIWIN brand.

The entire machine body adopts a honeycomb structure and is then integrally welded and formed; the cross beams are made of the same inner honeycomb steel structure, and the entire outer wall plate is bent and formed with an integral welding process; it then undergoes a secondary high-temperature annealing heat treatment process and is precision-machined by a large gantry milling machine. It has good rigidity and stability to ensure the parallelism and verticality of the machine.

The x, Y, and Z axes use Japanese Yaskawa l servo motors, which have high precision, high speed, and large inertia ratio performance and are stable and durable. The partitioned dust removal system and the opposite sealing layout at the lower end effectively remove a large amount of dust generated during cutting and provide a good working space for personnel.

YYC racks and linear guides adopt sealing protection devices to prevent oil-free friction movement and dust pollution, improve the service life of transmission parts, and ensure the accuracy of machine tool movement.

The professional Cypcut control system and networked operation ensure the cutting quality, making the cutting work more convenient and the operation simpler.

The laser cutting head is equipped with an imported capacitive non-contact height tracking system, which is responsive and accurate and avoids contact between the cutting head and

It can prevent the collision of processing plates, and can ensure the cutting focus position and stable cutting quality.

Cutting process parameters

| Thickness (mm) |

Maximum cutting speed (m/min) |

Material (gas) | Thickness (mm) |

Maximum cutting speed (m/min) |

Material (gas) | |

| 0.5 | 30.0-35.0 | Stainless steel (nitrogen) | 2 | 5.0-7.5 | Brass (nitrogen) | |

| 1 | 20.0-28.0 | 3 | 2.0-4.0 | |||

| 2 | 10.0-13.0 | 4 | 0.9-1.2 | |||

| 3 | 3.5-6.5 | 1 | 18.0-22.0 | Carbon Steel (Oxygen. KQ) | ||

| 4 | 3.0-4.5 | 2 | 6.6-8.0 | |||

| 5 | 1.8-2.5 | 3 | 3.0-4.5 | |||

| 8 | 0.5-1.0 | 4 | 2.8-4.0 | |||

| 1 | 13.0-25.0 | Aluminum alloy (nitrogen) | 6 | 2.0-2.8 | ||

| 2 | 7.0-12.0 | 8 | 1.4-1.8 | |||

| 3 | 4.0-6.0 | 10 | 1.0-1.3 | |||

| 4 | 2.5-4.0 | 12 | 0.9-1.2 | |||

| 8 | 0.5-1.5 | 14 | 0.6-0.75 | |||

| 1 | 9.5-15.0 | Brass (nitrogen) | 16 | 0.5-0.7 |

Note: The factors that affect cutting speed are complex and this table is for reference only.

Equipment operating cost analysis

Cutting auxiliary gas consumption

◆Cutting carbon steel plate (taking processing of 1mm carbon steel plate as an example)

The gas consumption per hour is about 0.7 bottles of oxygen, and each bottle of oxygen (pressure 15.5MPa, purity 99.5%) is about 20 yuan, so the hourly auxiliary gas consumption is: 14 yuan/hour.

◆Cutting stainless steel plates or aluminum alloy plates (taking processing of 1mm stainless steel plate and aluminum alloy plate as an example)

The gas consumption is about 4 bottles of nitrogen per hour. Each bottle of pure nitrogen (purity 99.99%, pressure 15.5MPa) is about 25 yuan, so the hourly assist gas consumption is: 100 yuan/hour.

illustrate:

If your company often cuts stainless steel plates or aluminum alloys, it is strongly recommended that your company use liquid nitrogen (purity 99.99%). The liquid nitrogen medium tank is 125KG, 320 yuan/tank, and can be used for 12 hours, 320/12=26.7 yuan/hour. The price of liquid nitrogen (99.99%) is about a quarter of that of bottled pure nitrogen (99.99%), and it saves the extra ventilation and downtime caused by frequent ventilation, as well as the waste caused by excessive bottled residual gas.

Key Words: Operating table half cover full side

Previous Page

Next Page

Welcome your message consultation

Recommend products