Focus position affects the cutting accuracy of fiber laser cutting machine

Release time:

2024-06-12

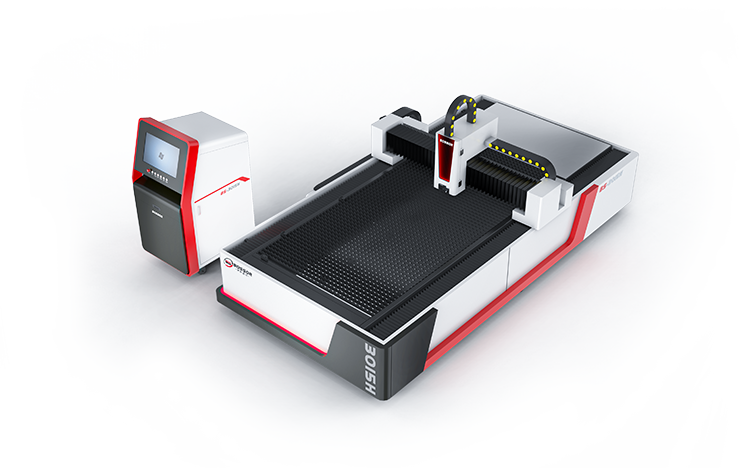

Factors affecting the cutting quality of fiber laser cutting machines include focus position adjustment. Since the density of laser power has a greater impact on the cutting speed, the selection of lens focal length is also an important issue. The spot size of the laser beam after focusing is proportional to the focal length of the lens. After the beam is focused by a short focal length lens, the spot size is smaller and the power density at the focus is high, which is beneficial to material cutting. However, its disadvantage is that the focal depth is short and the adjustment margin is small. The quantity is small and generally suitable for high-speed cutting of thin materials.

Factors affecting the cutting quality of fiber laser cutting machines include focus position adjustment. Since the density of laser power has a greater impact on the cutting speed, the selection of lens focal length is also an important issue. The spot size of the laser beam after focusing is proportional to the focal length of the lens. After the beam is focused by a short focal length lens, the spot size is smaller and the power density at the focus is high, which is beneficial to material cutting. However, its disadvantage is that the focal depth is short and the adjustment margin is small. The quantity is small and generally suitable for high-speed cutting of thin materials.

Since the telephoto lens has such a wide focal depth, it can be suitable for cutting thick workpieces as long as it has sufficient power density. After determining which focal length lens to use, the relative position of the focus and the workpiece surface is particularly important to ensure cutting quality. Due to the high power density at the focus, in most cases the focus position is just on the surface of the workpiece or slightly below the surface during cutting. Therefore, ensuring a constant relative position between the focus and the workpiece during the entire cutting process is an important condition for obtaining stable cutting quality.

Sometimes the lens is heated due to poor cooling during operation, causing changes in focal length, which requires us to adjust the focus position in time. When the focus is at the best position, the cutting slit is small and the efficiency is high. The fiber laser cutting machine can obtain better cutting results at the best cutting speed. In most applications, the beam focus should be adjusted to be just under the nozzle. The distance between the fiber laser cutting machine nozzle and the workpiece surface is generally about 1.5mm.

Latest News